Archive

Home > Archive

Connectivity is King

New EVO series is able to connect to ANY available MIS We support data-exchange via:

MQTT, RESTful services; Webservices; SFTP, TCP/IP

We provide Data/Reports in the following formats:

<xml>; PDF; (graphics in jpg and tiff); JSON soon (Q4/17)

Connectivity is King

New EVO series is able to connect to ANY available MIS We support data-exchange via:

MQTT, RESTful services; Webservices; SFTP, TCP/IP

We provide Data/Reports in the following formats:

<xml>; PDF; (graphics in jpg and tiff); JSON soon (Q4/17)

Tokyo Seimitsu Co., Ltd. completed the 6th building in Hachioji Plant. Building: Five story building with vibration control structure (Barrier-Free Design) Total Floor Area: Approximately 21,000 sqm (with approximately 3,000 sqm cleanroom)

Main Purpose of the 6th building are to increase production capacity for larger equipment and raise productivity in order to respond to the increasing demands of larger equipment. The launch of this new building can make it possible to dramatically improve production capacity for larger equipment (max 4 times).

The building has large cleanroom for larger equipment production and provides much more efficient production and technology development by connecting with the existing 3rd building. The new building has earthquake resisting structure such as vibration bumpers and lens shear damper and will be equipped with solar power panels to consider environment issues and energy saving.

‘Micro3Dslices’ gives operators one of the most accurate Laminography solutions in the market today, surpassing the current market benchmark. Bernhard Muerkens, VP Electronics said: “This exciting technology takes Laminography to a whole new level and gives clearly superior results much faster, really moving this technology into the semiconductor area. The new virtual rotation axis and unprecedented precision of the new manipulator assembly provide unrivalled inspection results, simplified operation, and higher inspection throughput.”

This solution is much more accurate than previous versions, due, in part, to the quality of design and engineering in the new manipulator assembly, allowing smaller and less dense features to be imaged than it was previously possible. This new technology produces vastly superior laminography results when compared to other systems which revolve the detector or use inferior manipulators.

The inspection of a complex assembly or component with ‘Micro3Dslices’ including the automatic analysis of the slice-by-slice images now takes less than 40 seconds per part, thanks to these developments. By means of the virtual rotation axis, the region of interest can be chosen at any point on the large inspection area and ‘Micro3Dslices’ can get started immediately, providing constant inspection results of highest precision and quality. Semicon and Wafer inspection also benefit greatly using the improved mapping technology and precise defect markings support the easy sorting of defective parts, another key requirement for this demanding market.

This new technology also offers a huge leap forward for all types of 2D imaging and the accuracy and repeatability for all types of inspection routines as well as analyses in the field of electronics applications, including QFN inspection.

The prototype will be presented for the first time at the SMT exhibition in Nuremberg, Germany.

The inspection of a complex assembly or component with ‘Micro3Dslices’ including the automatic analysis of the slice-by-slice images now takes less than 40 seconds per part, thanks to these developments. By means of the virtual rotation axis, the region of interest can be chosen at any point on the large inspection area and ‘Micro3Dslices’ can get started immediately, providing constant inspection results of highest precision and quality. Semicon and Wafer inspection also benefit greatly using the improved mapping technology and precise defect markings support the easy sorting of defective parts, another key requirement for this demanding market.

This new technology also offers a huge leap forward for all types of 2D imaging and the accuracy and repeatability for all types of inspection routines as well as analyses in the field of electronics applications, including QFN inspection.

The prototype will be presented for the first time at the SMT exhibition in Nuremberg, Germany.

Thermonics, Mansfield, MA (thermonics.com), a member of inTEST Thermal Solutions with Temptronic and Sigma Systems has developed a portable, low-temperature fluid chiller for MCT Worldwide, Minneapolis, MN (mct.com), improving strip handler equipment efficiency. MCT is the leader in strip test handlers for the semiconductor testing industry. The new chiller improves overall equipment efficiency for those customers performing cold testing down to -55ºC.

![]()

The chiller is equipped with on-board diagnostics that help predict chiller health and avoid unexpected downtime. An intuitive touch-screen interface allows for set up of thermal profiles, viewing data and trends, and logging diagnostics. Communications interfaces include (Ethernet, RS232, USB) for remote chiller control, including web browsers on mobile devices.

For more information on how MCT can reduce your cost of test, please contact us at sales@edgeworthcorp.com.

The chiller is equipped with on-board diagnostics that help predict chiller health and avoid unexpected downtime. An intuitive touch-screen interface allows for set up of thermal profiles, viewing data and trends, and logging diagnostics. Communications interfaces include (Ethernet, RS232, USB) for remote chiller control, including web browsers on mobile devices.

For more information on how MCT can reduce your cost of test, please contact us at sales@edgeworthcorp.com.

The best system for power device measurement with ACCRETECH's contact technology and wide applications combined with TESEC's measuring technology!

Features

Features

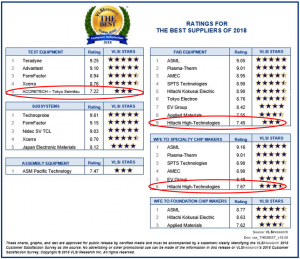

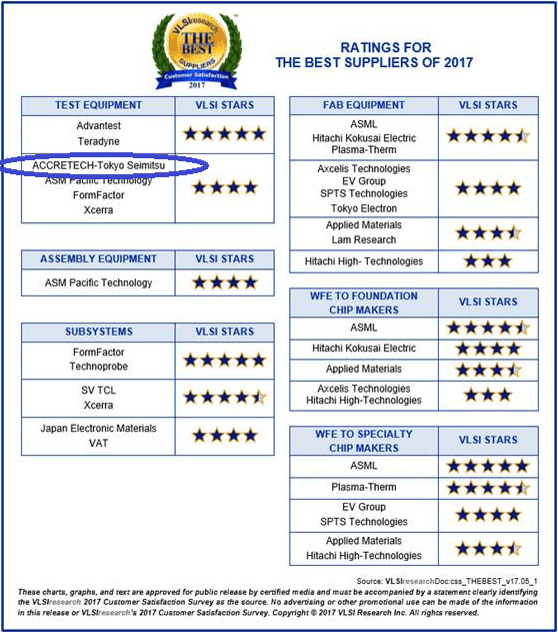

Congratulations to Accretech for placing in The Best Suppliers of 2017!

For more information, visit https://www.vlsiresearch.com.

Congratulations to Accretech for placing in The Best Suppliers of 2017!

For more information, visit https://www.vlsiresearch.com.

Edgeworth – A pioneer in its own right! While the Philippines was migrating to a more high-tech industrial nation and the electronics and semiconductor businesses growing from their infancy in this country, Edgeworth Marketing was established October 24, 1970.

Now, backed by more than 46 years of experience, we have remained as one of the pioneers and benchmarks of local representation, engaged in the marketing, sales, and after sales support of some of the world’s leading semiconductor assembly, quality control, failure analysis, and test equipment suppliers.

Later transformed to Edgeworth Corporation, our Company has gone through the same tides where the country has battled and similarly has successfully withstood the challenges.

With locations/support stretching as far south as Cebu, we can also be found in Laguna, Manila, Clark, Subic, Tarlac, and as far north as Baguio. We have established a sales and service presence for these key regions to remain at the forefront of customer support and satisfaction. Our strong and result-oriented management backed by technically trained engineers have created and maintained an image of reliability and efficiency to our customers.

Moving Forward

The needs of our customers are our key business. Satisfying them and working a win-win business relationship with them are the main reasons of our existence. Their demands are getting tougher and at the same time expected to be more cost-effective. Just-in-time-delivery, immediate sales and service support, training facilities and demo machines are some of the emerging challenges.

With these primary reasons, Edgeworth Laguna Inc. (ELI) was established inside the Laguna Technopark in Biñan/Sta. Rosa, Laguna. We moved closer to where our customers are, to be of service where it is needed, when it is needed.

One among the 8 warehouses of Omniworth Laguna houses ELI with its sales and service offices, parts control room, training and demo facilities. Under the Philippine Export Zone Authority (PEZA) registration, ELI enjoys the benefits of tax and duty free importations that make our system more effective in dealing with PEZA and BOI registered customers.

This is another milestone that a few has undertaken. 46 years of history and moving forward to our golden anniversary, Edgeworth remains your key partner for growth and success in the electronics and semiconductor industries in the Philippines.

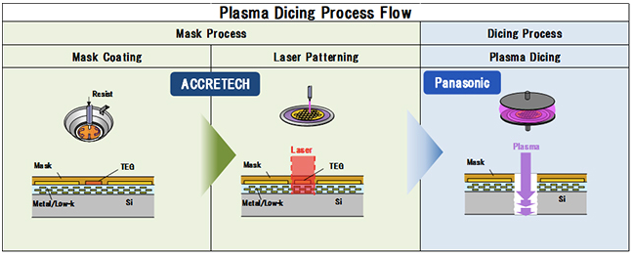

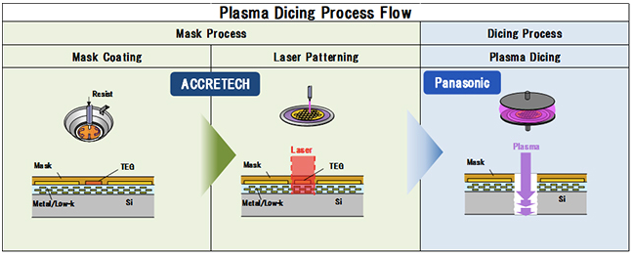

Tokyo Japan - Panasonic Corporation and Tokyo Seimitsu Co, Ltd (Hereinafter Tokyo Seimitsu) Today announced that Tokyo Seimitsu and Panasonic's subsidiary's company, Panasonic Smart Factory Solutions Co, Ltd (hereinafter PSFS) have started taking orders for the AL300P, Laser patterning machine for Plasma Dicing process jointly developed by the two companies. The AL300P is a new product design for the Plasma dicing process that achieves chips to be diced from a silicon wafer without damage.

Tokyo Japan - Panasonic Corporation and Tokyo Seimitsu Co, Ltd (Hereinafter Tokyo Seimitsu) Today announced that Tokyo Seimitsu and Panasonic's subsidiary's company, Panasonic Smart Factory Solutions Co, Ltd (hereinafter PSFS) have started taking orders for the AL300P, Laser patterning machine for Plasma Dicing process jointly developed by the two companies. The AL300P is a new product design for the Plasma dicing process that achieves chips to be diced from a silicon wafer without damage.

This is a Laser patterning machine developed exclusively for PSFS's Plasma dicing machine (APX300). The ALP300 enables a silicon wafer, to which a resist or other mask layer is attached in the pre-processing stage of Plasma dicing to be patterned at the dicing position with the specified width and high precision through UV laser processing.

Key Features of the New Product:

Tokyo Seimitsu's Laser Patterning Machine - AL300P

-This is a laser patterning developed exclusively for PSFS's Plasma Dicing Machine (APX300). The AL300P enables a silicon wafer, to which a resist or other mask layer is attached in the pre-processing stage of Plasma dicing, to be patterned to

This is a Laser patterning machine developed exclusively for PSFS's Plasma dicing machine (APX300). The ALP300 enables a silicon wafer, to which a resist or other mask layer is attached in the pre-processing stage of Plasma dicing to be patterned at the dicing position with the specified width and high precision through UV laser processing.

Key Features of the New Product:

Tokyo Seimitsu's Laser Patterning Machine - AL300P

-This is a laser patterning developed exclusively for PSFS's Plasma Dicing Machine (APX300). The AL300P enables a silicon wafer, to which a resist or other mask layer is attached in the pre-processing stage of Plasma dicing, to be patterned to

Plasma Dicing Process Flow

By Richmond Mercurio (The Philippine Star) MANILA, Philippines - The Philippine Economic Zone Authority (PEZA) plans to embark on an aggressive expansion of public economic zones across the country in which some will be offered "rent-free" to entice more foreign companies to set up shop in the Philippines. PEZA Director General Charito Plaza said, the agency is looking at building two new public economic zones per region, or a total of 36 across the country. Public economic zones refer to economic zones owned and operated by PEZA. "We are planning a massive economic zone expansion. We should build more economic zones, especially public economic zones because that is where bulk of our income (in PEZA) will come from. In private economic zones, what goes to us is 10 percent administrative fee plus the import and export permit. The rent of the industries go to the private developers. But if we have more public economic zones, the rent is ours," Plaza said. PEZA currently administers 366 economic zones across the country, 74 of which are manufacturing zones, 250 are IT parks, 21 are agro-industrial zones, 19 are tourism zones, and two are medical tourism parks. Of these economic zones, only four are owned by PEZA while the rest are from the private sector. The public economic zones are in Cavite, Mactan, Baguio, and Pampanga. Busines (Article MRec), pagematch: 1, sectionmatch: 1 According to Plaza, she is considering to give potential locators in these new public ecozones a 10-year, rent-free privilege. "We're looking into rent-free because we;re trying to benchmark by learning what the successful economic zones are doing. Successful economic zones include China, Japan, Vietnam and that is their attraction. For 10 years, they offered free use of the land so their public ecozones are rent-free," she said. At present, Plaza said rental rates across its four public economic zones are from P19 to P27 per square meter per month. This is compared to an estimated $5 per sqm month rental rate for private ecozones. The PEZA Chief said the push towards creation of more public economic zones across the country is a way to spur growth in the countryside. "I'm more particular in job creation and development of the countryside, development and productivity of our lands," Plaza said. For more information, go to http://www.peza.gov.ph/.

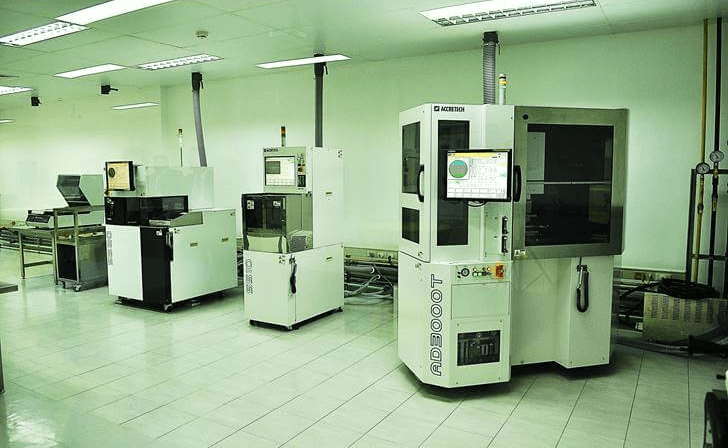

The Edgeworth Laguna Inc. Application Center Grand Opening was held in the Edgeworth Laguna Inc. office in Laguna Technopark, Special Economic Zone Biñan, Laguna on February 19, 2016.Our guests included members of the local government, Laguna Technopark, SEIPI, Senior Management from Accretech along with many from our esteemed customer base.

The Grand Opening featured the new Application Center which allows us to showcase our suppliers state of the art equipment locally, so that customers can evaluate our offerings without the hassle of leaving the country.

We also provide applications support using our tools so the customers do not have to stop running production to use their own tools.

In addition, we accommodate operator and technician training at the Application Center to give our customers hands on experience without having to give up valuable production time on their own equipment.

The Application Center will feature Semiconductor and Electronics Industry equipment from our broad base of suppliers. Watch for periodic announcements regarding upcoming product spotlights!

given to Edgeworth Laguna Inc. by Shindengen Philippines Corporation

Award Reads

“In recognition of it’s compliance to the Suppliers Requirements of SDP for the year 2015-2016 and its dedicated service which has contributed to the attainment of the company’s goal and objectives.

Given this 14th Annual Suppliers’ Forum on the 17th day of June 2016 at Shindengen Philippines Corporation 120 Excellence avenue corner Quality Drive, Carmelray Industrial Park 1, Canlubang, Calamba City Laguna”

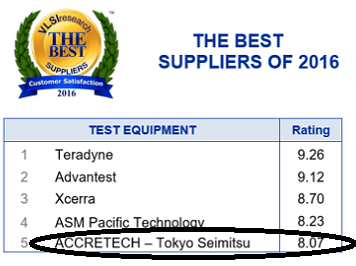

VLSI Research released "The Best Suppliers of 2016".

The list is grouped into FAB Equipment, Assembly Equipment, Test Equipment, and Subsystems. The customers rate the suppliers each year.

ACCRETECH placed 5th best in Test Equipment and is the only wafer prober manufacturer in the list.

Congratulations ACCRETECH!

For more information, visit https://www.vlsiresearch.com.

By Danessa Rivera (The Philippine Star) Energy Secretary Alfonso Cusi said, "the MOU is an initiative consistent with the long-term vision of President Rodrigo Duterte known as 'Ambisyon 2040' and compliments his 10-point socio-economic agenda." Senate PRIB/Joseph Vidal, File MANILA, Philippines - The Department of Energy and the Philippine Economic Zone Authority have signed a memorandum of understanding to accelerate the development of regional economic zones or ecozones in the country. "With the MOU in place, the country can expect the flow of critical investment which in the long-run creates more job opportunities and spurs rural development", Cusi said. Under the partnership, the DOE will develop energy policies to facilitate the reduction of the cost of doing business in the country, including the ecozones," the DOE chief said. "Energy efficiency programs, like the adoption of Energy Management Systems (ISO 50001), will be given importance to help the locator companies to be more efficient in their use of energy resources. This will result in lower power costs to sustain the companies' competitiveness, while also encouraging the establishment of more energy efficient ecozones in the country", Cusi said. The DOE secretary also underscored the importance of policies that would streamline the permitting processes for energy projects, to ensure stable and reliable supply of energy to drive economic activities in the ecozones. Since he took office, Cusi has stressed the need to streamline the process for power plants and to lower power rates during his term. In terms of bringing down electricity rates, he said the DOE was "looking at it from the perspective of the consumer." Currently, Philippine electricity rate-particularly that of Manila Electric Co. (Meralco) - is the third highest in Asia, fourth in Asia Pacific and 16th worldwide in 2016, based on a report done by Australia-based International Energy Consultants (IEC).

The Hitachi FT 150 XRF combines industry-leading detector technology with poly-capillary optics to offer high performance and repeatability of Ultrathin film measurements.

The poly-capillary optics achieve a 30um beam, allowing for enhancing the performance of ultra-thin measurements in small regions.